Unique integrated environment

Everything in a single environment

RDE is a software environment designed specifically for Robox Motion Controllers, which simplifies every stage of the life cycle of industrial automation applications. With a unified interface, RDE allows you to design, develop, debug, delivery and install control software quickly and reliably, using programming languages optimized for industrial automation.

With RDE, you can:

- Evaluate machine behavior in real time to identify and implement the best optimization strategies.

- Develop custom operator interfaces (HMI).

- Easly communicate with the system via Ethernet (TCP/IP), USB and legacy RS232.

- Manage and install software with ease, reducing deployment time.

Machine e system description

- Describe the controlled machine graphically by configuring axes, power sets, and robot kinematics.

- Define and map all fieldbus devices quickly and intuitively.

Project management

All resources, programs, parameters, device configurations and files can be managed in a single project, with the possibility to have multiple-project in the same workspace. Project are organized into intuitive windows:

- Configuration: Setup the device configuration, like axes, power sets, fieldbus, etc.

- Variables: Setup your application global variables and fieldbus mapping, global literally, global user alarm files, etc.

- Programs: Develop your code in multiple programming languages.

- Debugger: Run and debug code with breakpoints, live edits, live variables inspection and tracing tools.

- Monitor: Run a system monitor automatically generated from current project configuration.

- Flash: Manage the files for deployment on the flash of the Motion Controller.

Graphical configurators

The graphical configurator allow to describe both the hardware and software, easily and rapidly.

- The Fieldbus Editor (FBCED) to describe graphically any EtherCAT network, with full parametrization and PDO mapping, and more.

- The CAN Configuration Editor (COCED) allows to describe any CANopen network, full parametrization and PDO mapping, and more.

- The Path Library Editor (PLIBED) allows to edit and test the paths and points libraries

- The RTE Project also contains other configurators, for example:

- The axes group configurator, that allows group the axes and select from different kinematics, etc.

- The machine configurator, that allows to describe an axis, a power set, etc.

- The hardware configurator, that allows to select the Robox Motion Controller where the application will run.

- And more…

- The RDT project allows the development of customized human-machine interfaces (HMI) via a complete set of controls: configurable action buttons, comboBoxes, listBoxes, static and dynamic images, text fields (static, dynamic, editable), sliders and trends. Interfaces can include:

- actions

- macros

- help windows

- different management levels with password

- recipes libraries

- alarm history

- multi-language interface

- and many other utilitiesEach Motion Controller Robox can be associated to a serial device or a TCP/IP address thus allowing centralized diagnosis. The programs generated by RDT can run on the Robox RPC industrial PCs or, through the RTM software, on any PC Windows or Linux (the latest version can be downloaded with our Software Update Service).

Real-time monitoring e diagnostics

- The command shell allows live access to all entities on the Robox monitor controller, including digital and analog I/O, flash contents, file transfer, register reading/writing and configuration management.

- The system monitor allows live access to all entities like the command shell but via an easy to understand user interface.

- The variable monitor allows to display real-time values for any of the Motion Controller variable (for example, I/O, registers, structures, etc.).

- The graphical panel allows to design cockpit-style interfaces, to emulate external events (like I/O), in order to debug the motion controllers and also to interact with fieldbus devices.

- The graphical 3D panel allows to emulate graphically the machine’s behavior in a 3D environment.

Real-time graphical signal monitoring

- A fully featured oscilloscope displays up to 40 signals simultaneously for any instance (24 real-time + 16 calculated).

- Supports time-based or XY display, scale/offset adjustments, and synchronization.

- Supports start/stop triggers and automatic signals storage exportation.

- Supports real-time signal measurements.

- Data export capability.

System compability and requirements

Operating system

Microsoft Windows 11 x64, arm64 (build 22H2 and later) and Microsoft Window 10 x64 (build 1809 and later).

Communication interfaces

Serial (RS232/RS422), USB and Ethernet (TCP/IP).

Supported devices

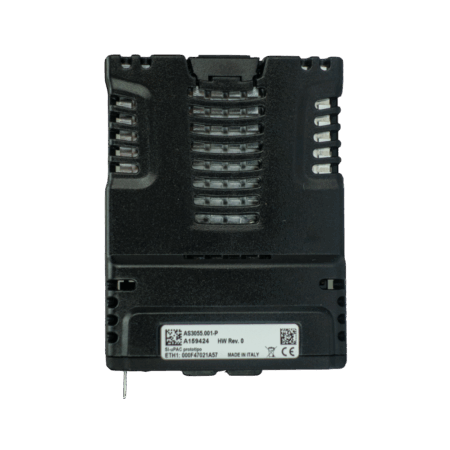

All Robox Motion Controllers

Minimum requirement

Intel I5 processor, 8 GB of RAM and 2 GB of free disk space, 3D capable graphic card (OpenGL).

Suggested requirement

Intel I7 processor, 16 GB of RAM.

Programming languages

RDE supports multiple languages for motion control, robotics, and logic:

| Language | Application | Features |

| R3 | Motion control (es. electronic cams, flying shear) | Structured text with libraries and live testing |

| RPE library for R3 and Object Blocks | Robotics (es. Pick&place, palletizing, drawing) | Axis group management, kinematic association, trajectory planning and motion along the trajectory |

| Ladder diagram (IEC 61131) | PLC programming | Graphical rung editor and online debugging |

| Object Blocks | Modular logic reuse | Advanced function blocks across languages written in C++ |

| R++ | Object-oriented development | Modern syntax for scalable applications |

| RPL | Robot Programming Language | Easy to use in robotic programming |

| RGcode | CNC paths (from CAD/CAM) | Direct G-code execution |

Download

The latest version of the software with a basic license can be downloaded via the Software Update Service | Rsetup.

The RDE, starting with version v3.11.0, is freely downloadable and usable for most of the planned activities, for teaching, maintenance and diagnostic purposes

The basic license activates automatically in the absence of other licenses and allows almost all activities with the following limitations:

- It is not possible to compile R3/R++/OB programs written in R3/OB language (RC3E compiler) and programs written in R++ language (RC4E compiler).

- It is not possible to compile AGV maps (ICMAP compiler).

- It is not possibile to compile RPL programs (RCXPL compiler).

- It is not possible to use LIVE modifications of ladder programs.

- It is not possible to use TEST mode for trajectory libraries (PLIB).

Developer licenses, which allow these functionalities, must be requested from Robox (support@robox.it).

These licenses are perpetual, include one year of updates, and can be installed on any number of PCs owned by the user.

The RDE tutorial is available on our YouTube channel at this link. You can also find additional training materials in the Teaching Materials section of our support page.