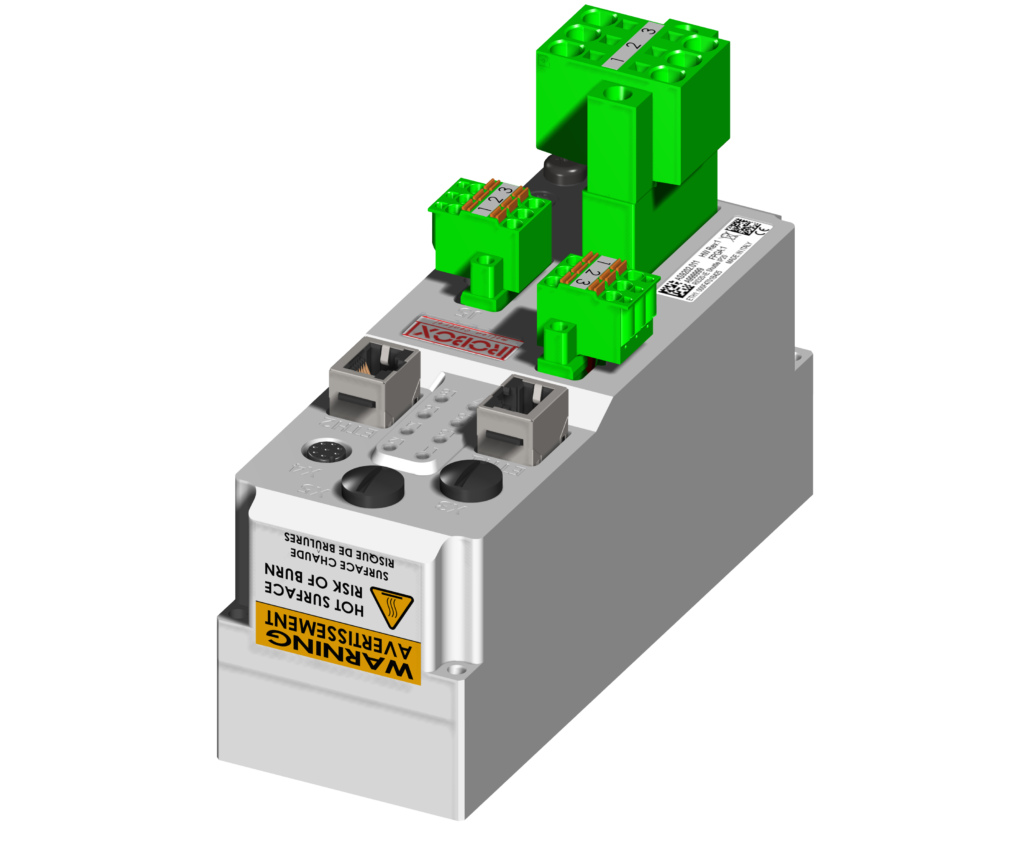

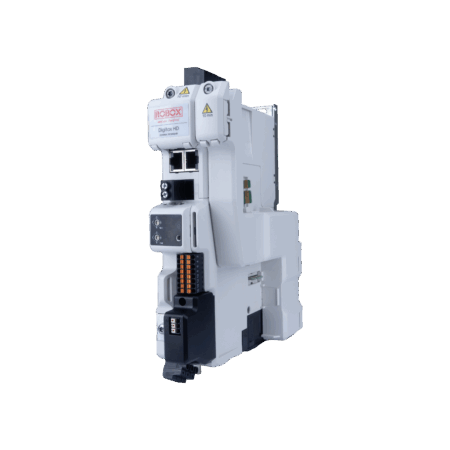

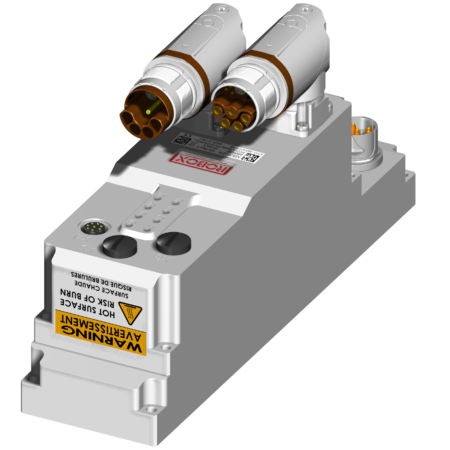

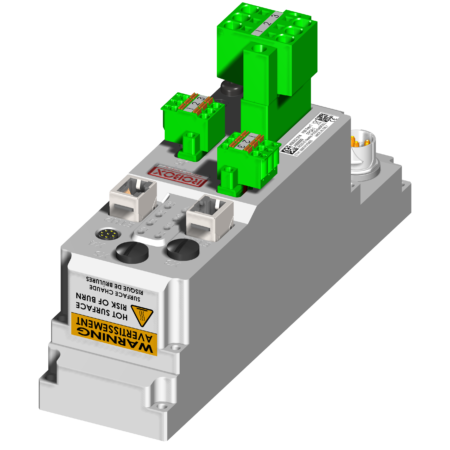

Space saving design

Servo drive EtherCAT with IP20 protection

RID20-IE Shuttle is designed for applications in protected environments, such as electrical panles or enclodes areas of a machine. Thanks to direct mounting on the motor, it allows for distributed logic and reduces overall footprint.

Compact and high-performing, it offers easy integration, optimized space management, and high performance in standard applications, ensuring reliability and IP20 protection.

Transducers and product variants

Available transducer interfaces are:

- ENDAT 2.1/2.2 (rotary/linear encoders)

- ENDAT 3 (rotary encoders)

- TamagawaSeiki (TS56xxaNxx, SA35-17/33bit-PLS5V)

- Resolver

- SinCos (linear motor with SinCos transducer)

- SSI (rotary encoders)

- Hiperface-DSL

- SanyoDenki (PA035-017BM001 singleturn)

- BiSS-C

- BiSS-C LinMot specific

Communication and diagnostics

- EtherCAT (CoE, FoE): main fieldbus communication

- RS232 interface: local service access

- Diagnostic LED: driver status indication

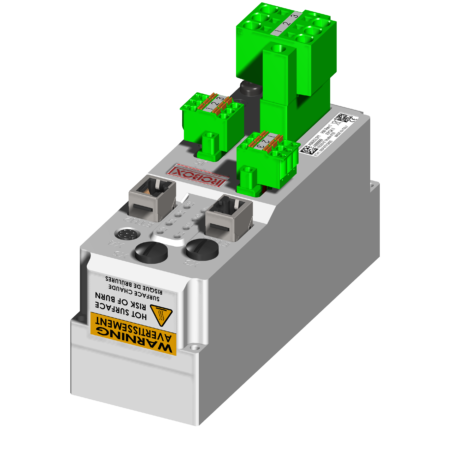

Connectors

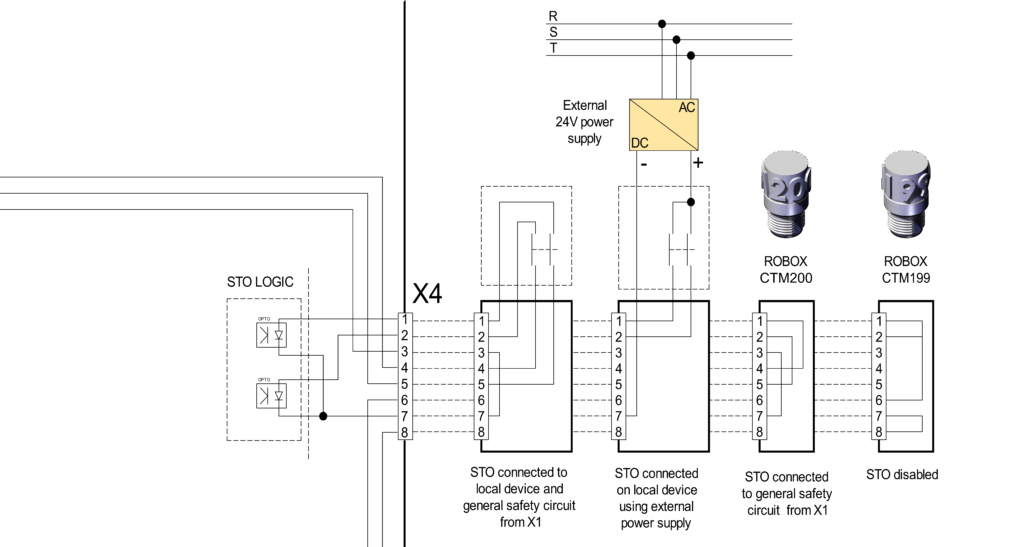

- 2 HTEC hybrid connectors, with rotatable angled receptacle, for power supply (800 VDC and auxiliary 18-36 VDC), fieldbus and torque off (STO) signals (common for all the drives in the chain)

- 1 M12 connector, RS232 and Holding-brake button signals

- 1 M12 connector, for input and output digital signals

- 1 M12 connector, for torque-off signals (local handle)

- 1 PPM SAMTEC connector for power motor phases

- 1 PMM SAMTEC connector for position motor transducer

- 1 PMM SAMTEC connector for holding brake

- 1 PMM SAMTEC connector for thermal motor sensor

Expandability

I/O’s default configurator

- 2 digital inputs, IEC61131-2 type 1, 24VDC (with debounce filter)

- 1 output/power-supply line (24VDC, up to 390mA), short-circuit and overcurrent protected, can be cycled as slow digital output

I/O’s configuration 2

- 1 digital input, IEC61131-2 type 1, 24VDC (with debounce filter)

- 1 digital output, 24VDC (up to 430mA), short-circuit and overcurrent protected

- 1 output/power-supply line (24VDC, up to 480mA), short-circuit or overcurrent protected, can be cycled as slow digital output

I/O’s Configuration 3

- Master IO-LINK (WIP)

- 1 output/power-supply line (24VDC, up to 390mA), short-circuit and overcurrent protected

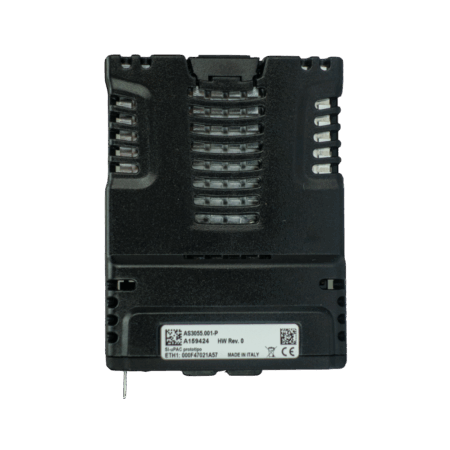

Mechanical and electrical specifications

- Power supply: up to 800 DC

- Auxiliary power supply: 18-36 VDC

- Maximum supported power: fino a 2KW

- External measures: 164 x 60 x 114 mm

- Weight: 1,2 kg

- Current, speed and position loops closed by the RID20-E

- Strong capability to support high temperatures and vibrations

- Internal 24VDC holding brake control driving up to 0.75A

- Internal accelerometer for vibration analysis (3 Axes)

Programming and interfacing

Parameterization and interface for RID20-E are managed via RDE, the Robox environment.