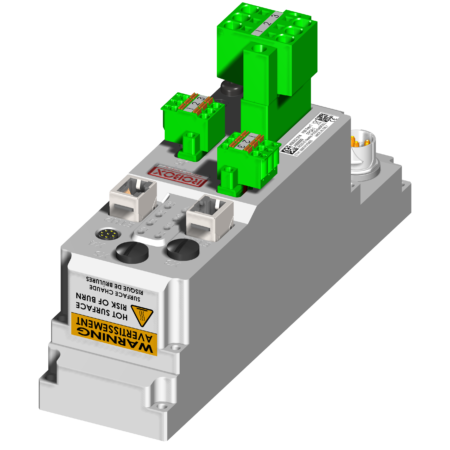

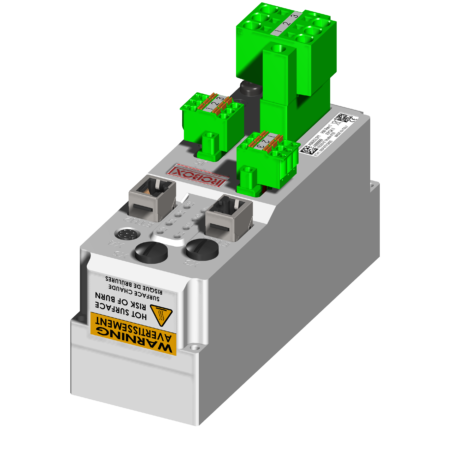

Space saving design

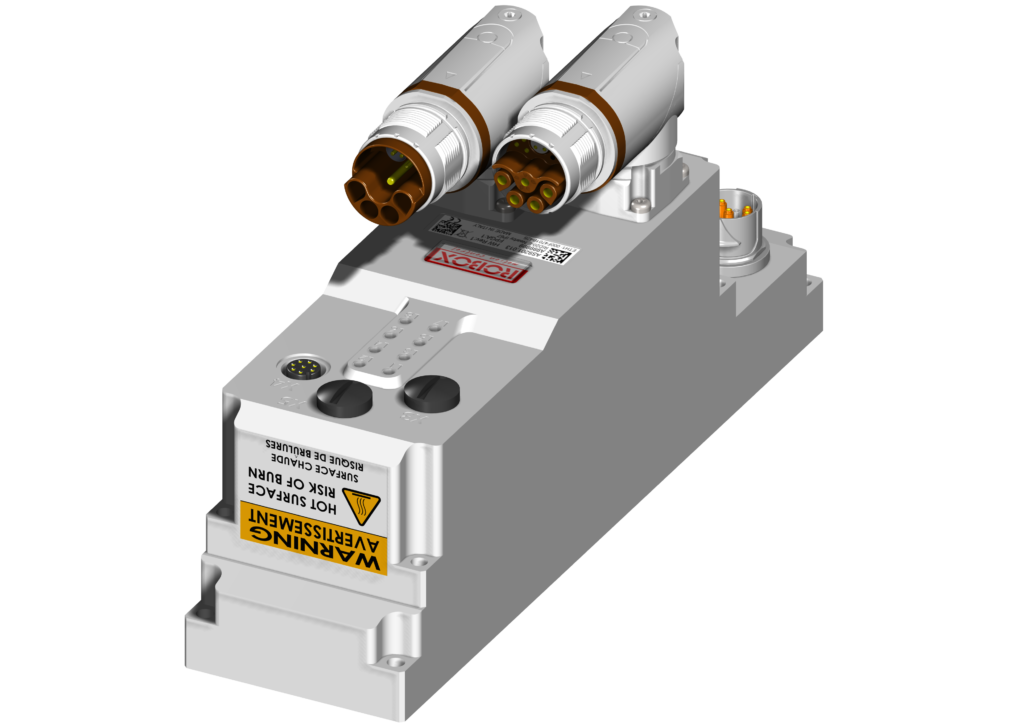

IP67 decentralized drive for reduced cabling

The Robox RID20-E servo drive is the optimal solution for implementing decentralized automation architectures. Designed for installation in close proximity to the motor (NEARBY), the RID20-E addresses space constraints and wiring complexity while ensuring the reliability and performance of a centralized system, even in demanding environments, thanks to its IP67 protection rating.

Transducers and product variants

AS9201.013 NEARBY IP67 version with dual motor connectors

Two ITEC connectors for motor connection, featuring TE connectivity:

- One connector dedicated to motor power, holding brake, and thermal sensors.

- One connector dedicated to motor position transducers and thermal sensors.

Supported position transducer interfaces:

- ENDAT 2.1/2.2 (rotary/linear encoders)

- TamagawaSeiki (TS56xxaNxx, SA35-17/33bit-PLS5V)

- Resolver

- SinCos (for tubular linear motors)

- SSI (rotary encoders)

- SanyoDenki (PA035-017BM001 single-turn)

- BiSS-C

- BiSS-C LinMot specific

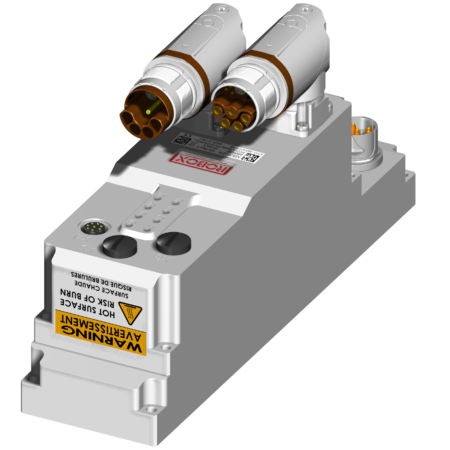

AS9201.014 OC “One Cable” version with single hybid connector

A single hybrid ITEC connector integrating all motor and sensor connections:

- Simplified connection compared to AS9201.013, with reduced cabling.

- Includes motor power, holding brake, thermal sensors, and position transducers in one connector.

Supported position transducer interfaces:

- Hiperface-DSL (rotary encoders)

- EnDat 3 (rotary encoders)

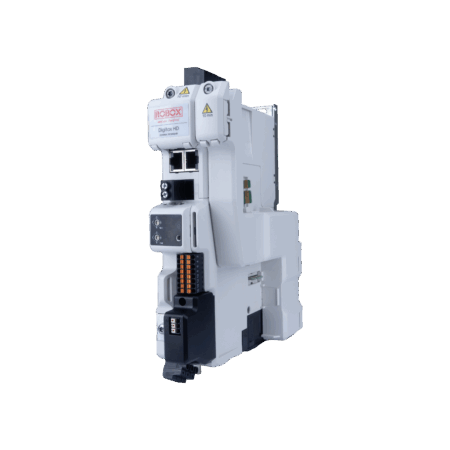

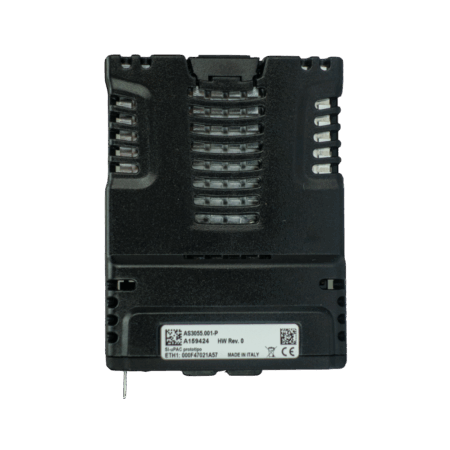

RID20-IE IP20 AS9202.013/014

Both versions are available with IP20 protection rating for indoor and protected environments.

Communication and diagnostics

- EtherCAT (CoE, FoE): main fieldbus communication

- RS232 interface: local service access

- Diagnostic LED: driver status indication

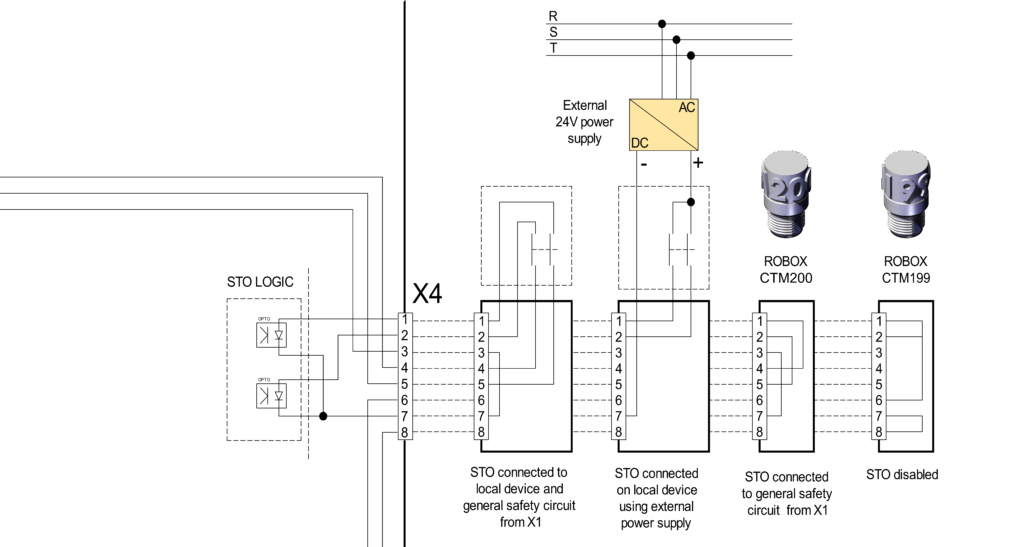

Connectors

- 1 or 2 HTEC hybrid connectors, with rotatable angled receptacle, for power supply (800 VDC and auxiliary 18-36 VDC), fieldbus and torque off (STO) signals (common for all the drives in the chain)

- 1 M12 connector, RS232 and Holding-brake button signals

- 1 M12 connector, for input and output digital signals

- 1 M12 connector, for torque-off signals (local handle)

- 1 ITEC connector for power motor phases, holding brake, thermal sensor

- 1 ITEC connector for position motor transducer, thermal sensor

Expandability

I/O’s default configuration

- 2 digital inputs, IEC61131-2 type 1, 24VDC (with debounce filter)

- 1 output/power-supply line (24VDC, up to 480mA), short-circuit and overcurrent protected, can be cycled as slow digital output

I/O’s configuration 2

- 1 digital input, IEC61131-2 type 1, 24VDC (with debounce filter)

- 1 digital output, 24VDC (up to 430mA), short-circuit and overcurrent protected

- 1 output/power-supply line (24VDC, up to 480mA), short-circuit or overcurrent protected, can be cycled as slow digital output

I/O’s configuration 3

- IO-LINK master (WIP)

- 1 output/power-supply line (24VDC, up to 390mA), short-circuit and overcurrent protected

Mechanical and electrical specifications

- Power supply: up to 800 DC

- Auxiliary power supply: 18-36 VDC

- Maximum supported power: up to 2KW

- External measures: 220 x 60 x 116 mm

- Weight: 1,5 kg

- Current, speed and position loops closed by the RID20-E

- Strong capability to support high temperatures and vibrations

- Internal 24VDC holding brake control driving up to 0.75A

- Internal accelerometer for vibration analysis (3 Axes)

Parameterization and interface

Parameterization and interface for RID20-E are managed via RDE, the Robox environment.

RID20-E is certified by