The main features are:

The tool allows communicating with the AGVs:

- via radio modem and serial connection

- via wireless LAN on TCP/IP or UDP protocols

PLC communications:

- with serial interface RS232

- with OPC server

- through ethernet with send/receive or fetch/write protocols

- generically by reading/writing a file

Database data exchange with:

- SQL server

- MySql

- PostgresSQL

- ODBC

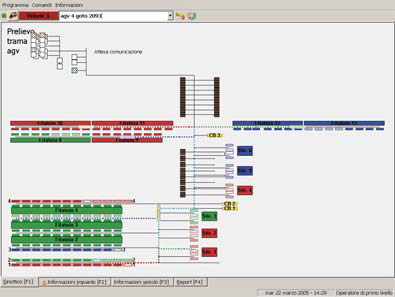

Controlling multiple AGV concurrent movements:

- managing anti-collision and priorities algorithms between AGVs

- evaluating the best path to assign to an AGV considering the direction of the path and the AGV orientation, as defined in the plant map

Gives to the user a full integrated development environment (x-script) to define AGV’s movements with these advantages:

- great flexibility and adaptability to any plant requirements and customization

- no need for external compilation tools

- processing informations received through the native interfaces of AGV Manager or exchanging data by other means (sockets, etc.)

- the ability to integrate “plugins”, specific for a precise application, to increase the capabilities of AGV Manager for the needs of a specific plant

This post is also available in: Italian